Cold process soap making has definitely taken off in the world of cosmetics. Here we take a look at the fabrication process of an authentic surgras soap that is sure to hydrate your skin all year long!

What is cold process soap?

Also known as cold saponification.

Saponification is a chemical reaction provoked by mixing a fat (oils, butters, etc) with a strong base (for solid soap, the strong base is sodium hydroxide lye, for liquid soap the strong base is potassium hydroxide, also known as potash).

This reaction creates two elements: glycerin and soap! A cold processed soap is ready the moment all the lye has been chemically transformed and there is none of it left. In order for all the lye to be transformed into soap, the oils or butters are used in excess to be sure that all the lye is transformed. The leftover fatty acid is what we call surgras. Surgras, is a French word that translates into exactly what it is: the excess fat. Surgras is known for its nourishing, softening and protecting the skin.

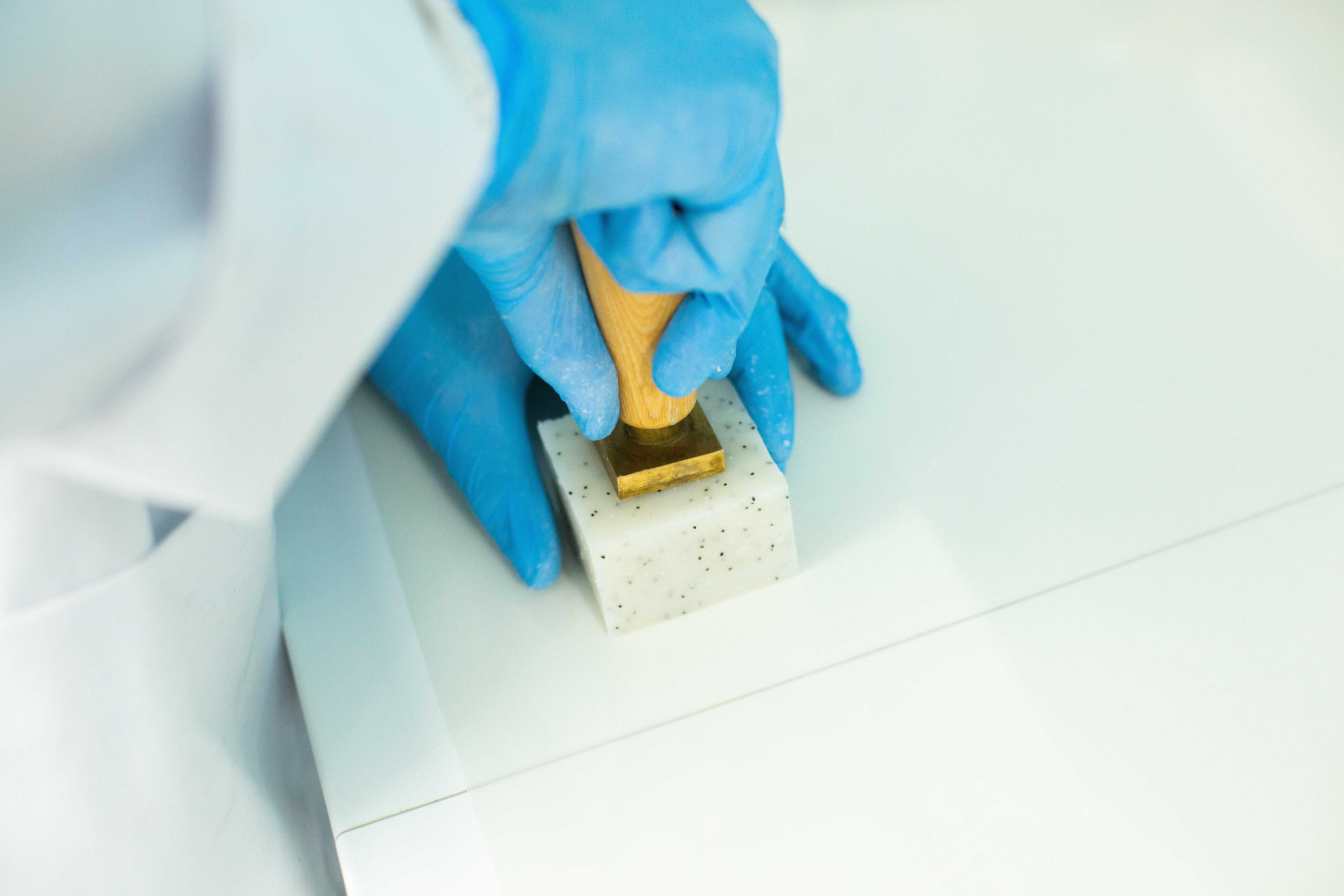

The main indicator to know that the oils and lye are reacting with one another is “the trace” left by the mixture as the oils and lye begin to emulsify. The trace will appear in about 5 minutes of mixing. Certain soap makers prefer to incorporate their precious oils at the moment the trace develops in order to conserve their natural properties.

Like its name indicates, cold process soap making does not use heat. This is contrary to hot process soap making, where the soap is cooked for 10 days at 100°C, then washed and the glycerin is also removed. Cold process soaps are saponified at room temperature, with no warming or rinsing. Sometimes oils can be slightly warmed to achieve a homogenous mixture (for example, when adding coconut oil to a recipe).

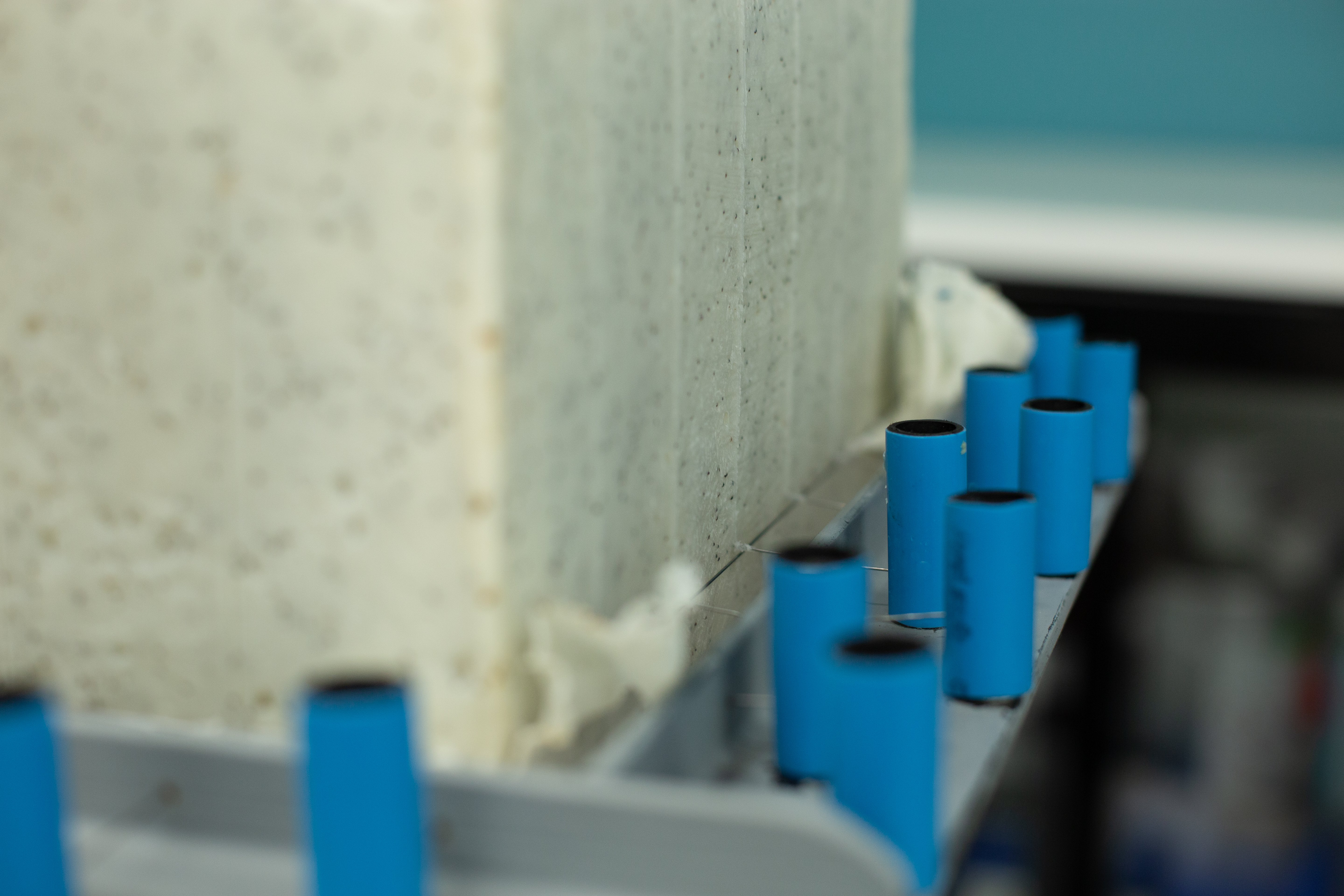

Cold process soapmaking is quite long. Once the mixture has been poured in a mold, the soap must be cured. This drying process is typically a minimum of 4 weeks. This allows the saponification to completely finish and the soap to dry.

Hydrated and protected skin

In cold process soaps, the ingredients are not heated, which allows them to conserve their beneficial and natural properties. This type of soap is also less aggressive because of the surgras present. The skin retains its hydrolipidic film after having been washed, which gives it extra hydration and protection.

This is a real advantage for when we don’t have time to put on our lotions after the shower!

A process that respects the environment

The environmental impact is reduced when practicing cold process soap making due to the fact that there is no heating period. This process therefore requires very little energy.

This ancestral technique requires time and patience, the soap is made in smaller batches as well!

Certain soap makers, whether we are talking about cold process or hot process, go even further in the idea of zero-waste by reusing the soap flakes or noodles to make detergent, new recomposed soap bars, etc.

A great DIY opportunity

Cold process soap making is also something you can do youself. Just be sure to follow the recipe use the correct measurements and handle the lye with caution (it’s a corrosive product, wear the correct protective gear!)

The rest is left up to you, play around with your creative side: add plant or mineral based dyes to color your soap, use essential oils for their natural benefits and fragrance!

Cosmébio labelled cold process soaps